The Characteristics of Lithium Ion Battery

A lithium-ion or Li-ion battery is a type of rechargeable battery which uses the reversible reduction of lithium ions to store energy. It is the predominant battery type used in portable consumer electronics and electric vehicles. It also sees significant use for grid-scale energy storage and military and aerospace applications. Compared to other rechargeable battery technologies, Li-ion batteries have high energy densities, low self-discharge, and no memory effect (although a small memory effect reported in LFP cells has been traced to poorly made cells).[9]

Chemistry, performance, cost and safety characteristics vary across types of lithium-ion batteries. Most commercial Li-ion cells use intercalation compounds as the active materials. The anode or negative electrode is usually graphite, although silicon-carbon is also being increasingly used. Cells can be manufactured to prioritize either energy or power density.[10] Handheld electronics mostly use lithium polymer batteries (with a polymer gel as electrolyte), a lithium cobalt oxide (LiCoO

2) cathode material, and a graphite anode, which together offer a high energy density.[11][12] Lithium iron phosphate (LiFePO

4), lithium manganese oxide (LiMn

2O

4 spinel, or Li

2MnO

3-based lithium rich layered materials, LMR-NMC), and lithium nickel manganese cobalt oxide (LiNiMnCoO

2 or NMC) may offer longer lives and may have better rate capability. NMC and its derivatives are widely used in the electrification of transport, one of the main technologies (combined with renewable energy) for reducing greenhouse gas emissions from vehicles.[13][14]

M. Stanley Whittingham discovered the concept of intercalation electrodes in the 1970s and created the first rechargeable lithium-ion battery, which was based on a titanium disulfide cathode and a lithium-aluminum anode, although it suffered from safety issues and was never commercialized.[15] John Goodenough expanded on this work in 1980 by using lithium cobalt oxide as a cathode.[16] The first prototype of the modern Li-ion battery, which uses a carbonaceous anode rather than lithium metal, was developed by Akira Yoshino in 1985, which was commercialized by a Sony and Asahi Kasei team led by Yoshio Nishi in 1991.[17]

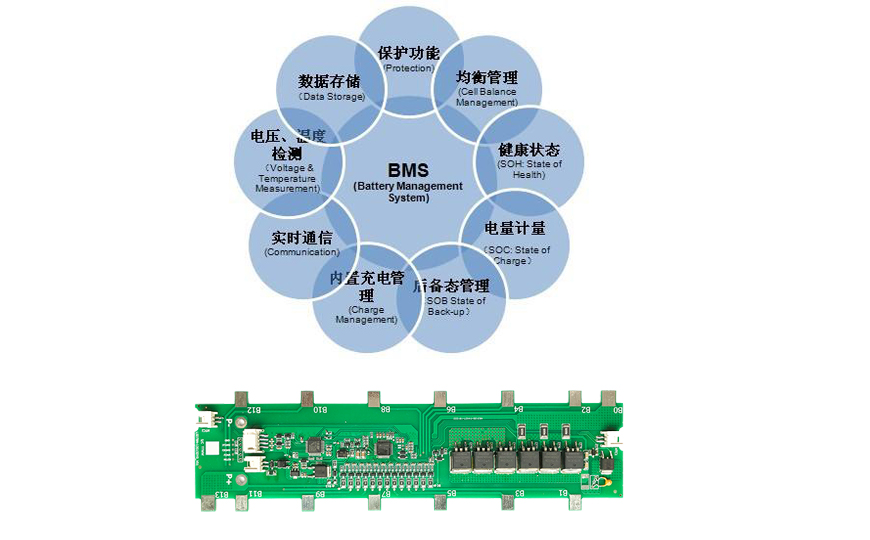

Lithium-ion batteries can be a safety hazard if not properly engineered and manufactured since cells have flammable electrolytes and if damaged or incorrectly charged, can lead to explosions and fires. Much development has made progress in manufacturing safe Lithium-ion batteries.[18] Lithium Ion All Solid State Batteries are being developed to eliminate the flammable electrolyte. Improperly recycled batteries can create toxic waste, especially from toxic metals and are at risk of fire. Moreover, both lithium and other key strategic minerals used in batteries have significant issues at extraction, with lithium being water intensive in often arid regions and other minerals often being conflict minerals such as cobalt. Both environmental issues have encouraged some researchers to improve mineral efficiency and alternatives such as iron-air batteries.

Research areas for lithium-ion batteries include extending lifetime, increasing energy density, improving safety, reducing cost, and increasing charging speed,[19][20] among others. Research has been under way in the area of non-flammable electrolytes as a pathway to increased safety based on the flammability and volatility of the organic solvents used in the typical electrolyte. Strategies include aqueous lithium-ion batteries, ceramic solid electrolytes, polymer electrolytes, ionic liquids, and heavily fluorinated system.